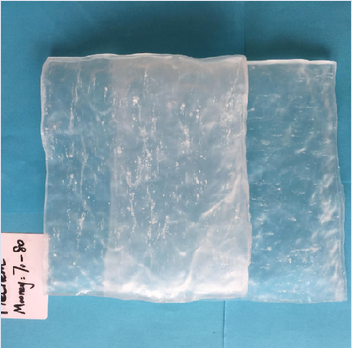

FKM Copolymer Raw Gum

Properties

|

Item |

C20 | C30 | C40 | C50 | C70 | C120 |

|

Appearance |

White or light-yellow sheet, no visible impurities | |||||

| Fluorine Content % | 66 | 66 | 66 | 66 | 66 | 66 |

| Density(g/cm3) 23℃ |

1.82±0.02 |

1.82±0.02 |

1.82±0.02 |

1.82±0.02 |

1.82±0.02 |

1.82±0.02 |

| Mooney viscosity(ML(1+10)121℃) | 25±5 | 35±5 | 45±5 | 55±5 | 75±5 | 120-140 |

| Tensile strength after press cure(MPa) 177℃, 10min≥ | 8.0 | 8.0 | 9.0 | 9.0 | 9.0 | 9.0 |

|

Tensile strength after post cure(MPa) 230℃, 24H≥ |

10.0 | 10.0 | 11.0 | 11.0 | 11.0 | 12.0 |

| Elongation at break after press cure(MPa)177℃, 10min≥ | 180 |

180 |

180 |

180 |

180 |

180 |

| Elongation at break after post cure(MPa)230℃, 24H≥ | 160 |

160 |

160 |

160 |

160 |

160 |

| 200℃ 70H Compressibility 20% Compression set(%)≤ | 20 | 20 | 20 | 20 | 20 | 12 |

| 200℃ in No.3 jet fuel, weight increase after 24H(%)≤ | 5 | 5 | 5 | 5 | 5 | 5 |

| Water Content(%)≤ | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.1 |

1. The experiment results above are based on the laboratory authorized by our company, which can be used for reference. Your test results may have some difference if the process of mixing, test equipment and test method are different.

2. Rubber compounds recipe: FKM 100g; AF 2.0g; BPP 0.5g; MgO 3.0g; Ca(OH)2 6.0g; N990 30g. Press Cure 177℃@10min; Post Cure 230℃@24hour.

FreChem FKM Raw Gum Naming System:

FC20/T20F:Represents Jiangsu FreChem Co., Ltd;

C: Represents fluoelastomer family;

“C” means copolymer of vinylidene fluoride and hexafluorpropene;

“T” means terpolymer of vinylidene fluoride, tetrafluoroethylene and hexafluorpropene;

20: Represents nominal Mooney Viscosity of the product; the data could be 20-180, represents that the Mooney viscosity is 20-180;

W: represents wide molecular distribution

Processing and Storage Precautions:

2. Precaution for processing:During the processing, it should avoid compounding gum with metal powder or amines (content more than 10%), otherwise violent reaction will occur. Fluoroelastomer will release a little toxic gas such as fluorine hydride and fluorine acid during vulcanization,so good ventilation in the processing place is very important. Smoking is prohibited in work area. Please wash your face and hands carefully when you leave the working area.

3. Precaution for storage:Fluoroelastomer should be stored in clean, cool and dry place because it is sensitive to water and light.

Hotline:+86 25 5218 4416

Hotline:+86 25 5218 4416

Email: info@frechem.cn

Email: info@frechem.cn